Echi Pouch Manufacturing Facility

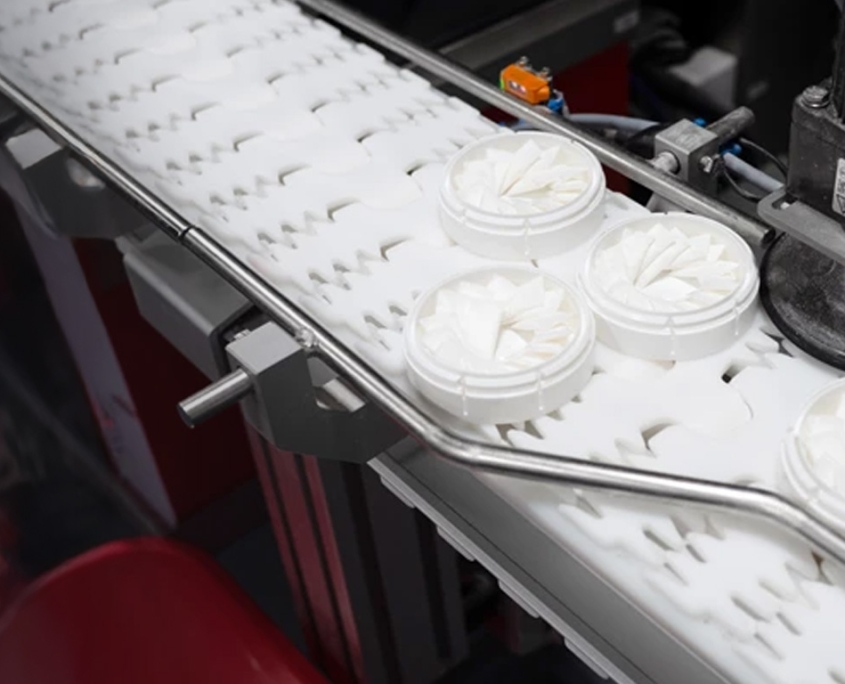

Echi is a leading manufacturer of nicotine pouches. We maintain rigorous quality control at the production source to ensure the highest quality in smokeless nicotine products. We have consistently received recognition from distributors and end-users for our services and products. Now, let’s take a closer look at the Echi nicotine pouch factory and explore how nicotine pouches are produced.

When was the Echi Nicotine Pouches&Strips factory established?

At Echi, our team is composed of highly skilled technicians and senior engineers who specialize in nicotine technology. Our dedicated R&D department, made up of nicotine experts, is continually pushing the boundaries of innovation, ensuring that our products lead the market in quality and performance.

Founded in 2019, Echi’s founder has been at the forefront of developing synthetic nicotine technology. With over eight years of in-house research and development, our team consistently creates cutting-edge products that enhance the competitiveness of our nicotine pouches and provide unmatched value to our partners.

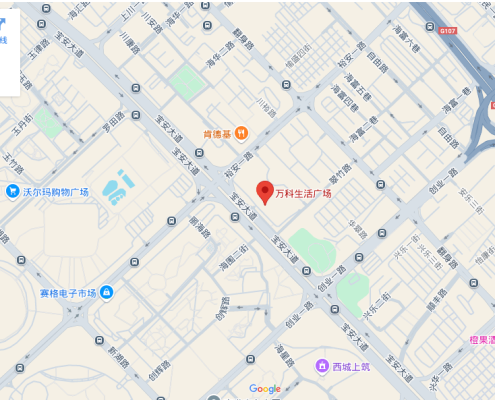

Where is the Echi Nicotine Pouch&Strips factory located?

Echi’s manufacturing facility is located at No. 3 Dongpo Street, Yangmei Community, Bantian Street, Longgang District, Shenzhen, Guangdong, China. Situated within a modern industrial park, our large production workshop is equipped with cutting-edge technology. We adhere to stringent quality control protocols to ensure that all products meet the highest safety and quality standards.